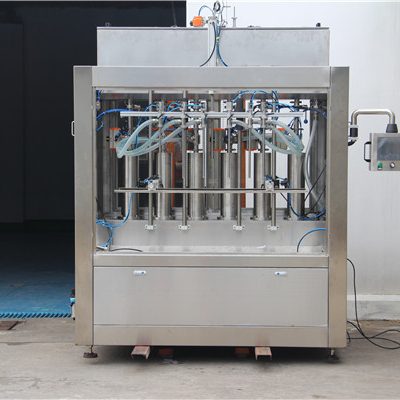

This machine adopts serve weighing type filling system to calculate the filling volume of big barrel products. The machine adopts PLC control, according to the filling bottle, fixed discharge mouth, the rest of the operation can be finished on the touch screen. It's widely used in food, chemical, medical, cosmetic, agrochemical industries, etc. It is suitable for liquid filling, especially for high viscosity materials such as oil, lube oil, Mobil oil, lubricant oil, liquid soap and foam liquid.

仕様書

5ガロン/ 3ガロン/ 20L / 12L / 6L / 4L / 5Lバレル

バレル充填機

上昇充填キャッピング機能

2000BPH容量機

マシンキャラクター

1. the rinsing main transmmission is by pneumatic action: the cylinder push the gear, then gear drives rinsing main shaft to rotate, the rinsing position move stablely, and the gear structure can ensure the rinsing rightly to bottle mouth center.

2. When rinsing, filling valve goes into the bottle, the filling time is controlled by magnetic valve to ensure the full filling. The filling time is adjustable to meet full filling requirement

3. When filling action is over, the cylinder push the bottle to capping position, the cap cover the bottle mouth, then cap pressed onto the mouth. After cap pressing action finished, bottles are put out

4. it is easy to sample from sterilizing water tank or make the sterilizing water. The stainless steel filtering net protect the impurity matter from water tank

5. In the rinsing tunnel, there is plastic cutting means enclosure to guard the sterilizing water or alkali water from going outside

| モデル | QGF-100 | QGF-200 | QGF-300 | QGF-450 | QGF-600 | QGF-900 | QGF-1200 |

| 塗りつぶし | 1 | 2 | 3 | 4 | 8 | 8 | 8 |

| ボトルサイズ | 5ガロン | 5ガロン | 5ガロン | 5ガロン | 5ガロン | 5ガロン | 5ガロン |

| ボトルスペック(mm) | 270×490 | 270×490 | 270×490 | 270×490 | 270×490 | 270×490 | 270×490 |

| 生産能力(BPH) | 100 | 200 | 300 | 450 | 600 | 900 | 1200 |

| 圧力源(Mpa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.6 | 0.6 | 0.6 |

| Gas Consumption(m3/min) | 0.37 | 0.37 | 0.6 | 0.8 | 1 | 1.5 | 1.8 |

| モーター力(kw) | 1.38 | 1.75 | 3.8 | 3.8 | 7.5 | 9.75 | 13.5 |

| 電圧(V) | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ | 380V / 50HZ |

| 重量(kg) | 680 | 800 | 1500 | 2100 | 3000 | 3500 | 4500 |

クイック詳細

タイプ:充填機、特殊

条件:新しい

アプリケーション:飲料

包装タイプ:バレル

包装材料:金属

自動グレード:自動

駆動型:空気圧

パワー:4KW

原産地:上海、中国(本土)

ブランド名: VKPAK

材料:SUS304またはSUS316

A 5L barrel filling machine is a specialized piece of equipment designed to fill 5-liter barrels or containers with various types of liquid products. This machine is ideal for use in industries such as oil, chemical, and food processing, where accurate and efficient filling of barrels is essential.

The machine consists of several components, including a filling head, a barrel feeding system, a conveyor system, and a control panel. The filling head dispenses the liquid product into the barrel with high accuracy, ensuring that each barrel is filled to the correct level.

The barrel feeding system uses a system of sensors and guides to ensure that the barrels are fed into the filling machine in the correct position and at the correct speed. The conveyor system transports the barrels through the machine, ensuring that they are filled and ejected at the correct time.

The control panel allows operators to adjust the machine's settings and monitor its performance, ensuring that the filling process is running smoothly and efficiently. The machine can be programmed to fill different types of liquid products, making it versatile and adaptable to the needs of different production lines.

The 5L barrel filling machine is designed for high efficiency, with the capacity to fill multiple barrels simultaneously. The machine is also easy to use and maintain, with all components easily accessible for cleaning and maintenance.

The machine can be equipped with additional components such as a capping system or a labeling system, allowing for a fully automated filling, capping, and labeling line.

Overall, the 5L barrel filling machine is an essential piece of equipment for industries that require accurate and efficient filling of liquid products into barrels. It ensures that the products are correctly measured, packaged, and protected, maintaining the quality and integrity of the product.